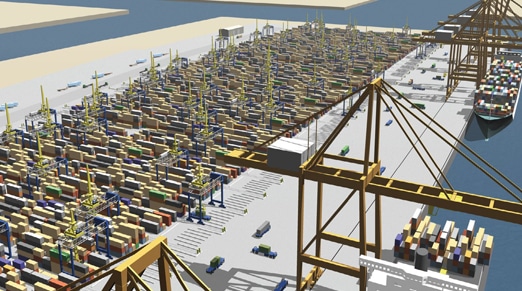

- Physical flows describe the movement of goods and services within all or part of a system. These can be packages and pallets in an automated warehouse, or passengers in an airport.

- Dynamic simulation allows the reliable and accurate prediction of the performance of production and logistics systems in relation to business needs.

- Dynamic simulation is also a privileged test environment for diagnosing systems and testing optimisations.

For a successful dynamic simulation

- Have an excellent understanding of the logical processes of the system, i.e. knowledge of the decision points and the rules that apply to them.

- Build up clean data representative of the intended activity of the system, ideally directly from the system or a similar activity.

- This provides the ingredients for a model that is as close as possible to the real system, which is the only way to guarantee the fidelity of the analysis.

Upstream and downstream of projects

- Prediction of system performance,

- Testing of multiple scenarios,

- Understanding and visualisation of system operation,

- Dynamic 3D graphical representation,

- Anticipation of blocking points,

- Identifying areas for improvement and testing optimisations,

- In all fields: automated and conventional warehouses, automated storage and handling systems, order preparation systems, automotive production lines, airport flows, etc.

Our experience on many fronts

- SDZ ProcessRéa has an experience in dynamic simulation with discrete events, in particular via the mastery of the Witness Horizon tool; establishment of a computer model of your installation, diagnosis and optimisation for any type of scenario.

- Thanks to its expertise, SDZ ProcessRéa has the necessary skills to meet the challenge of static and dynamic simulations of Process suppliers.